The cost performance of ceramic ball valves is determined by evaluating the balance between their cost and the value they provide in terms of performance, durability, and long-term benefits. Here are some factors to consider when assessing the cost performance of ceramic ball valves:

1. Upfront Cost: Ceramic ball valves generally have a higher upfront cost compared to metal valves due to the specialized materials and manufacturing processes involved. However, it's important to consider the total cost of ownership over the valve's lifespan rather than focusing solely on the initial cost.

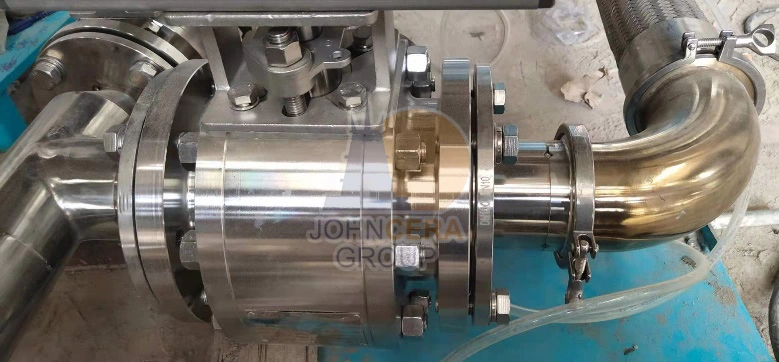

2. Durability and Service Life: Ceramic ball valves offer exceptional durability and longevity compared to many metal valves. Their resistance to wear, corrosion, and high temperatures can result in longer service intervals, reduced downtime, and lower maintenance and replacement costs over time.

3. Reduced Maintenance and Operational Costs: The superior chemical resistance and wear properties of ceramic ball valves can minimize the need for frequent maintenance, repairs, and replacements. This can result in cost savings in terms of labor, spare parts, and production downtime.

4. Performance in Harsh Environments: Ceramic ball valves excel in harsh environments where metal valves may corrode, degrade, or fail. The ability of ceramic ball valves to withstand corrosive fluids, high temperatures, and abrasive media can ensure reliable operation, reduce the risk of process interruptions, and lower the overall cost of operation.

5. Energy Efficiency: Ceramic ball valves often require less actuation force or torque to operate compared to metal valves, resulting in potential energy savings in valve actuation systems. The reduced energy consumption can contribute to overall cost savings in energy-intensive applications.

6. Reduced Contamination Risks: Ceramic ball valves offer excellent chemical inertness and resistance to leaching, reducing the risk of fluid contamination. This can be particularly important in industries such as pharmaceuticals, food processing, or semiconductor manufacturing, where product purity is critical and contamination can lead to costly recalls or process inefficiencies.

7. Customization and Adaptability: Ceramic ball valves can be customized to specific application requirements, allowing for optimal performance and functionality. This customization capability can lead to improved efficiency, reduced system complexity, and cost-effective solutions for unique applications.

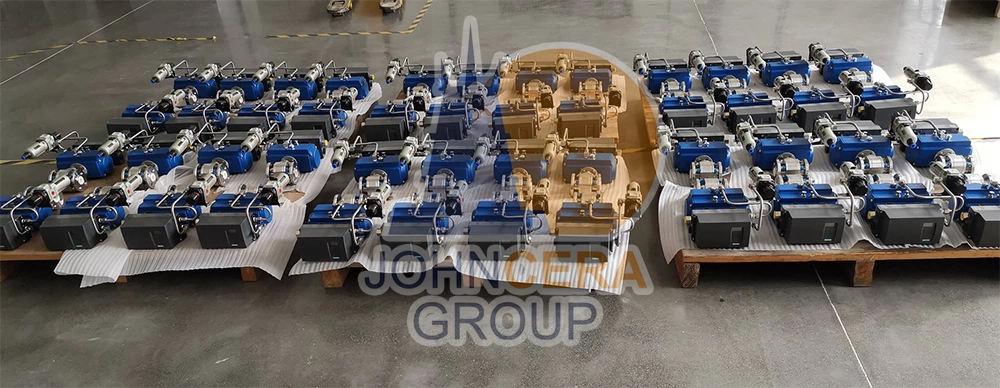

When evaluating the cost performance of ceramic ball valves, it is essential to consider the specific requirements of the application, the expected lifespan of the valves, and the potential cost savings associated with their superior properties. Consulting with JOHNCERA VALVE manufacturers, conducting cost-benefit analyses, and considering long-term factors can help assess the overall cost effectiveness and value proposition of ceramic ball valves.

Email Us

[email protected]