Ceramic ball valve makes up for the shortcomings of traditional metal valve. High-quality ceramic ball valves have many advantages such as corrosion resistance, wear resistance, erosion resistance, good sealing performance, small thermal expansion, good heat insulation, and small torque, which can effectively extend the service life of the valve.

Of course, this also means that there are high requirements for the production of ceramic lined ball valves. One important point is the control of trace elements in the production of ceramic ball valves, which is of great significance to the material of ceramic valves. So why exactly? Johncera Group takes you in-depth discussion of ceramic ball valves and their production process quality control knowledge.

Why is the control of trace elements important to the material of ceramic ball valves?

1. The control of trace elements will affect the thickness of the ceramic valve housing. High-quality ceramic ball valves should have a solid body, high hardness, and good mechanical properties to ensure easy maintenance. This is deeply affected by the chemical elements in the main material. If the trace elements are not well controlled, these characteristics of the ceramic ball valve will be affected.

2.High-quality ceramic valves have good corrosion resistance to most acid and alkali media. This depends not only on the ceramic ball valve manufacturer's process treatment, but also on the chemical elements of the ceramic ball valve material. If the trace element is not well controlled, it will inevitably affect the nature of the chemical elements, thus affecting the material of the ceramic lined ball valve.

In the industry, there are national standards for the chemical elements in ceramic valve materials. The control of trace elements is of great significance to the material of ceramic ball valves. Of course, as a perfect substitute for metal valves, it is of course worthy of our strict control of its quality.

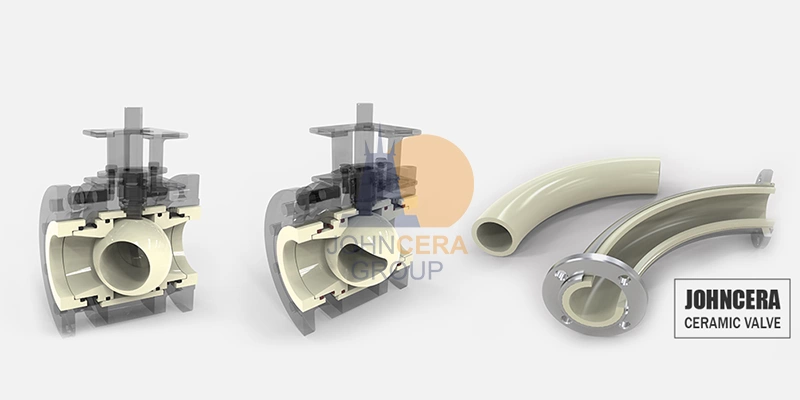

Performance advantages of ceramic ball valves

1. Ceramic lined ball valves have excellent performance such as corrosion resistance, abrasion resistance, good heat insulation, etc., which greatly extend the service life of the valve.

2. The ceramic ball valve has a solid body and good stability. Using it can improve the safety of the equipment and is convenient for maintenance.

3. With modern and advanced structural design, coupled with its own superior properties, the ceramic ball valve has good sealing performance, which can minimize leakage and protect the environment.

4. The preparation of metal valves requires a large amount of metal materials and mineral resources, and the production of ceramic valves can save the use of these metal materials, especially some rare mineral resources.

In general, strict control of trace elements can ensure the material of ceramic valves and produce high-quality ceramic valves. Johncera Group is a professional ceramic ball valve manufacturer with 30 years of experience. Our products have excellent corrosion resistance. The hardness of the ceramic valve ball is as high as HRA88, the sealing performance reaches the ANSI VI level, low torque value, and long service life. It is widely used in most industries. Welcome to consult, our rich experience and knowledge can give you the most professional answer. If you are looking for high-quality ceramic ball valves, we will be a good choice.