Johncera is a professional manufacturer of ceramic valves. With almost 30 years experience in the industry, our ceramic valves have successfully dealt with many severe working conditions, such as power plant, waste incineration, paper and pulp, chemical, fertilizer, coal chemical, and petrochemical. Professional production: ceramic ball valve, ceramic V-type controlling valve, ceramic rotary valve, ceramic double gate valve, ceramic knife gate valve, ceramic semi-ball valve, ceramic butterfly valve, ceramic slide valve, ceramic wear-resistant pipe and other products. Our valves have the characteristics of corrosion resistance, erosion resistance, zero leakage, self-lubrication and long service life. Our products exhibit high stability and excellent mechanical properties under very severe engineering application conditions.

With the continuous progress and development of science and technology,

ceramic materials from the formulation, molding, processing and assembly technology

and other aspects of technology more mature and complete. Ceramic valves and

excellent performance has also been recognized by more and more people in the valve industry.

In industries where valves applied, the use of metal valves has become as common as the convention. In applications that metal valves are not functioning well, industry insiders are more used to expect that the improvement of metal materials can resolve the issues. However, with the continuous development of industrial facilities and the upgrading of standards and requirements, metal materials are not always the best choice due to their natural properties, causing them unable to operate under severe working conditions.

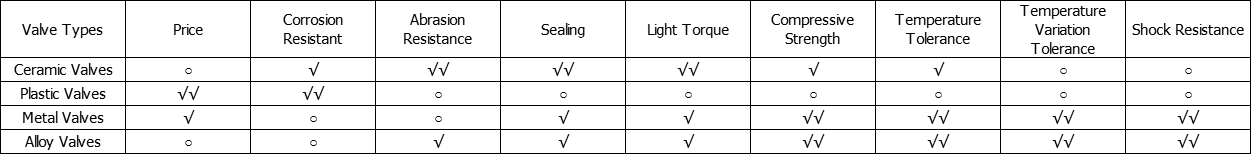

Therefore, the development and application of ceramic valves will naturally become an alternative to fill the traditional valve's disadvantages. Ceramic valves have the benefits of corrosion resistance, wear resistance, high sealing performance, and low torque. Other advantages are listed in the below chart, which compares the four most common valve types.

The development of high efficiency, high quality and low cost precision

machining technology for ceramic materials has become a hot issue in the

field of ceramic engineering at home and abroad.

—— Zhipeng Xie, Structural Ceramics (Tsinghua University Press)

Looking for customised ceramic valve solutions?

According to different medium, pressure, temperature and other special conditions,

the ceramic valve can be customized to meet the needs of users

Find us at [email protected].

Email Us

[email protected]